Ed Lawson, Head of Content at The Retail Hive, sat down with Ian Howes of Sainsbury’s to discuss the accelerating shift to automation in retail, the pressures driving it, and what lies ahead for the industry.

Read on to discover more…

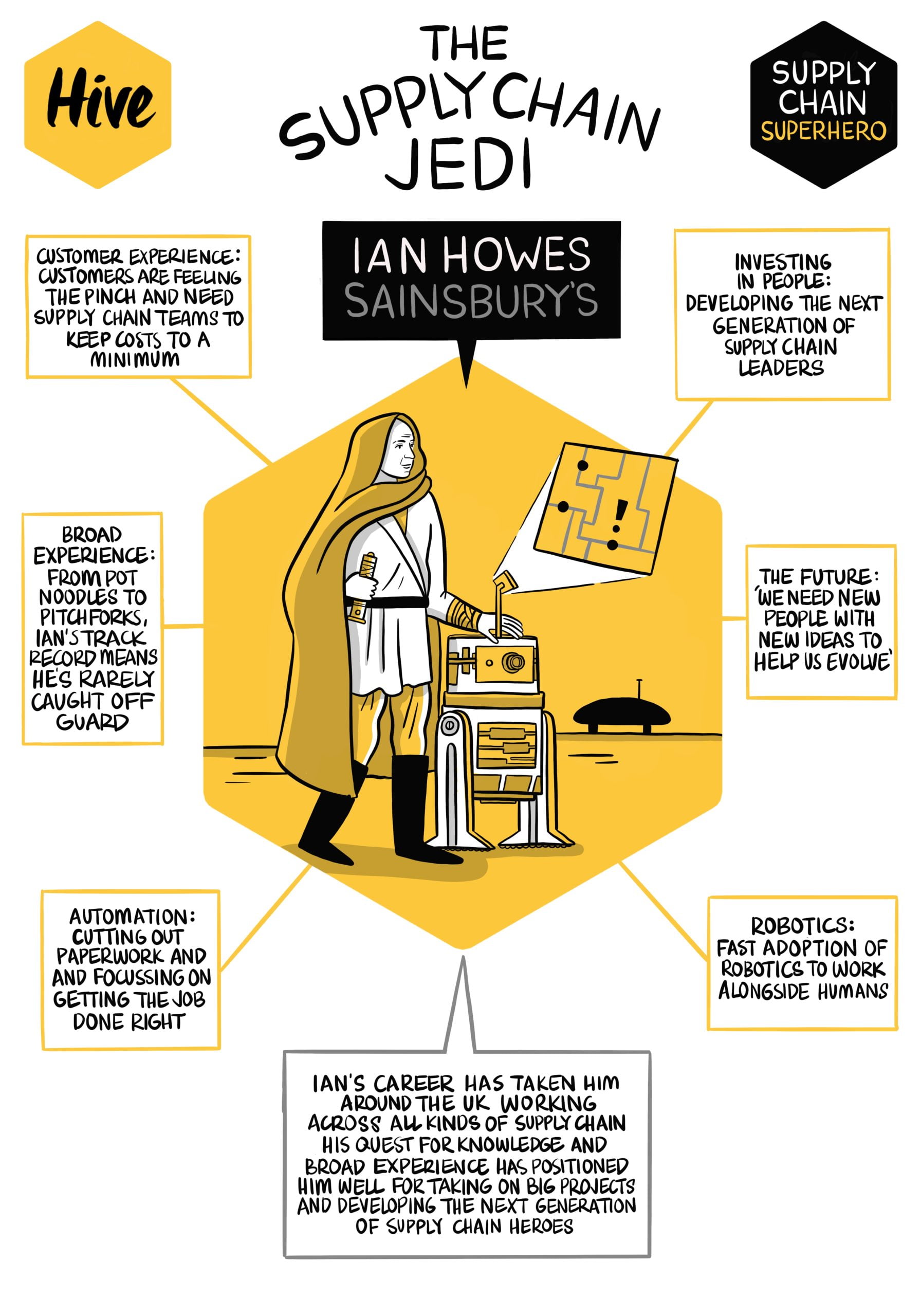

Ian Howes

Ed Lawson

Workforce challenges have been a recurring theme in retail operations. How do you see these pressures shaping the push towards automation?

They are significant. We are dealing with demographic changes, rising prices, and an industry that struggles to attract and retain people. Operations and supply chains have an image problem, and motivating the workforce has become harder. Add to that the increasing demand for warehouse space, and the pressure to find sustainable solutions is obvious. This is not just about efficiency anymore, automation is becoming essential for survival.

How has automation in retail evolved over time?

The trend started back in the 1990s with big box automation: large warehouses designed to drive efficiency. By the 2000s, it was about automating to compete on cost. Today, it is about automating to win. Over the next few years, it will be about keeping up. In the short term, automation is about surviving the workforce, industry and macroeconomic challenges. Those who move first have the potential to unlock real competitive advantage.

This is not just about efficiency anymore, automation is becoming essential for survival.”

Where is Sainsbury’s vs. the wider market, on this journey?

Whilst some in the market are lagging, others are moving towards fully autonomous operations. Walmart, for example, has committed $15 billion to automation over the next 10-15 years. In the UK, Tesco has announced its London Gateway facility, and M&S has announced major automation plans. From a general merchandise perspective, Amazon has been on this journey with Kiva robots for years, and Home Bargains has also made significant investment to future-proof their Supply Chain. Those who get ahead will be able to reinvest the gains into price, which is the ultimate driver of competition.

What about the immediate gains? How is automation delivering value today?

Automation can drive significant productivity improvements. It takes time to optimise, but the medium- to long-term gains are commercially attractive with large cash injections required up front. The warehouses of the future will be far more intensive, with greater throughput in the same footprint. And it is not just big box automation: visibility, tracking and AI are advancing quickly. Think about dynamic delivery, efficient route planning, RFID, all now affordable, with AI layered over the top. These simplify operations, improve service and take cost out.

Large-scale automation takes years to deliver. What can be done in the interim?

Big box projects have a four to five year lead time, so robotics will be especially prominent in the meantime. Amazon has shown what is possible. At Sainsbury’s, we are investing in Lowpad AMRs, which brings products to pickers. It is lower cost, faster to implement, and drives immediate efficiency. We have also implemented robots that can autonomously unload containers. And we are seriously looking at humanoid robots. Boston Dynamics and others are making rapid progress. Within five to ten years, humanoids will be part of our operations, so we are investigating the use of proofs of concept with a couple of companies very soon.

Automation is not about replacing people, it is about adapting to these realities.”

That is a big step. How do you see the role of humanoids in retail operations?

Initially, they will complement colleagues in the back of house. I don’t think we will see them front of house for at least 10-15 years, but the pace of change is fast. It is evolving quickly, and retailers need to keep an open mind.

Beyond robots, where do you see the biggest future shifts?

Machine learning and AI for planning and efficiency will be critical, and electrification of fleets will be a massive agenda point. We need to hit net zero by 2035. Autonomous vehicles would be great, but they are still a long way off. In the meantime, AI and electrification are where the immediate impact will come.

With all this technology, will humans still have a role?

Absolutely, but the workforce will look different. We are seeing an ageing workforce, which means older and less productive colleagues, and a younger generation that wants to work when it wants. Their mentality is different. Automation is not about replacing people, it is about adapting to these realities. The real challenge is to implement well, take colleagues with us, and develop leaders that are fit for this future state. That means working with strategic partners, hiring people who can see how technology might evolve, and applying it in a five to ten year horizon. Logistics and fulfilment is at a major turning point. It will increasingly adopt new technologies, robotics and automation, and there is no better time to be in the industry as our customers want greater levels of immediacy.

See you next year?

We can’t wait to reconnect with our members at next year’s Supply Chain Leaders Exchange!

When? 14th-15th May 2026

Where? Venue to be confirmed, but you can expect sumptuous surroundings as usual!

Who? This meeting is exclusively for senior retailers in the supply chain and fulfilment sector, with the opportunity to meet best-in-class solution providers